MAD Logistics

Fast – reliable – climate-friendly

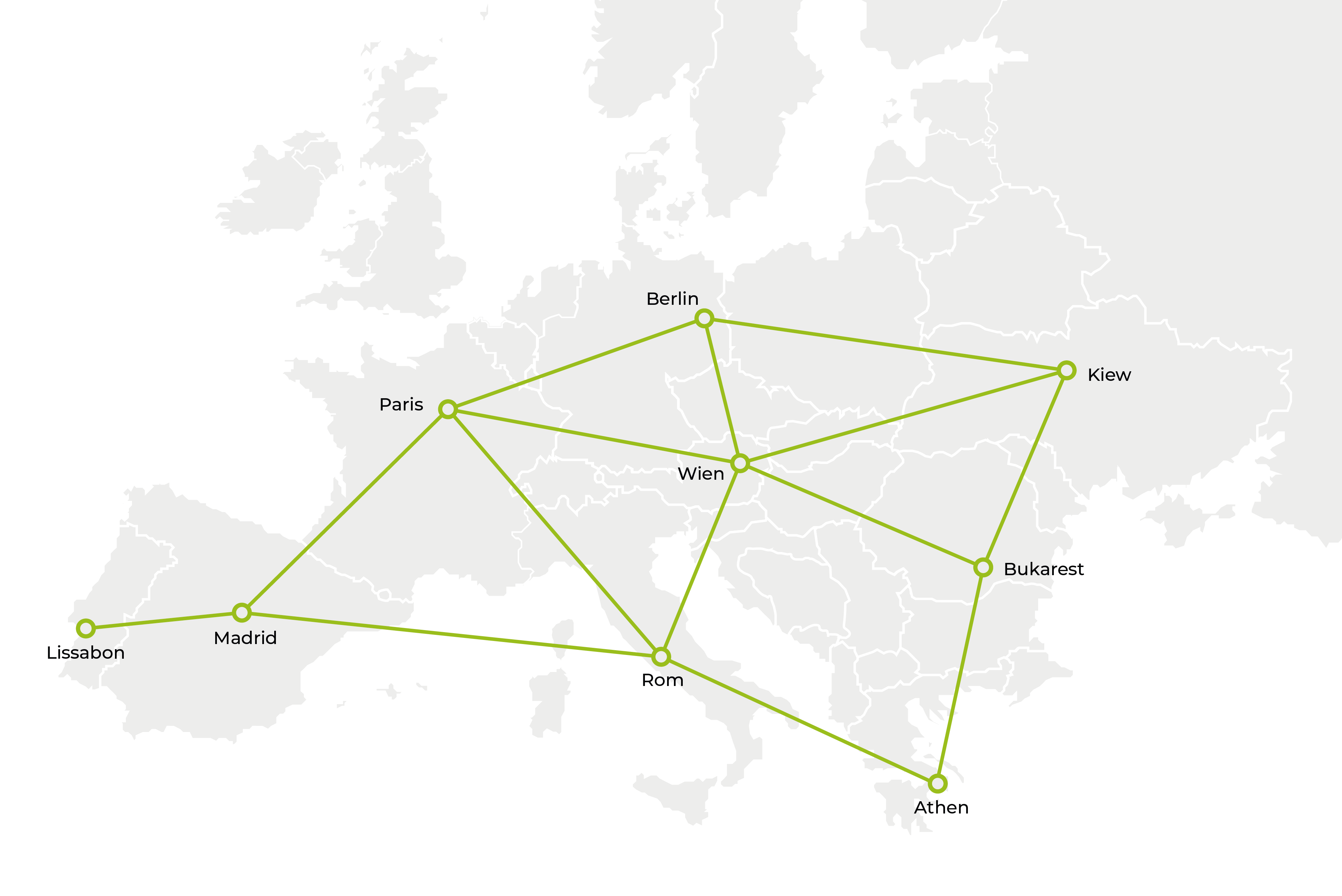

We optimize the transport of biodiesel and diesel from tank farm to tank farm with our rail logistics and consistently rely on environmentally friendly rail transportation in order to ensure the most climate-neutral transport possible.